I lowered my car a couple inches back in the 90's. While the car handles much better with this setup, the rear end has much higher rear camber than stock, and under hard acceleration it squats even worse yet.

While the original design is adjustable by using different brackets (3 different brackets which can be used in different combinations to get the camber right), Richard Good of Goodparts has come up with a much slicker setup. His setup looks much like a stock bracket with a vernier adjuster grafted into it. Definitely a top notch assembly for getting your camber right.

I decided to install the Goodparts Brackets, along with a new set of his Nylatron bushings to improve the action of my suspension.

For the installation, I used Richard's instructions, along with some helpful hints from BobbyD's website (link to the right--->)

Before I started, I measured the car to get some data. This was my starting point.

Left Front: 1.6 degrees

Right Front: 1.4 degrees

Left Rear: 3.7 degrees

Right Rear: 3.2 degrees

I dug into the install and it went pretty quickly. A few photos are below.

I did reinstall all the original alignment shims so that I would not change the rear toe settings. While I was in there, I measured up the alignment shim and drew this. It might help me or someone else down the road.

When everything was installed, it was time to adjust everything (that is the whole point!). I found that the instructions call out a certain amount of adjustment per turn of the adjuster bolts, however that unfortunately did not work as planned. In the end, I made several adjustments per side to get them right.

Some installation observations:

- Don't bother installing these adjustable brackets without doing the Goodparts nylatron bushings with them. (how-to on Bobby-D's site is great)

- Do all of your grease zerk installation prep before you do the bushing fitting.

- The arm with brackets will go on and come off the frame much easier if the arm is hanging down almost vertical. If sticking out like it would be going down the road, the body will get in the way.

- Keep a pad and pen ready to write down your toe alignment shims and what combo goes inside/outside.

- Take 'before' measurements of both camber and ride height (I did not do ride height and I'm now trying to do this via old photos...)

- Make sure to shoot a squirt of grease in your outer axle universal joint while you have the hub removed!

- You do not need to disconnect your brake lines if you are very careful to hang the brake backing plate up out of the way while you do the other work.

When I installed the brackets, I installed them with the inside bracket with 1/2" between the bottom of the adjuster and the bracket on the inside, and 1/4" on the outside bracket. This adjustment made the following change:

Starting- Left Rear 3.7 Right Rear 3.2

New Brackets-Left Rear 2.5 Right Rear 2.2

I then put 5 turns down on the left rear and 4 turns down on the right rear (both outside adjusters)

First Adjustment result Left Rear 2.2 Right Rear 1.8Finally, I put 3 turns down on the left rear outside, 1 one up the inside and 2 turns down on the right rear outside

Final Adjustment result Left Rear 1.4 Right Rear 1.3

The handling of the car now feels more solid, and comments from my friends indicate that the car does not squat nearly so much upon hard acceleration. All those things are great. I'm pretty doggone happy with that!

Monday, December 29, 2014

Tuesday, October 14, 2014

2014 6-Pack TRials - Oxford

Finally got to attend a TRials. It was great to finally meet some friends in person (Ken/Poolboy, Irv/Elwood, etc) and to see some old friends as well. So much fun to hang out with everyone and see everyone's cars.

I'll let the photos tell the story.

I'll let the photos tell the story.

Tuesday, September 30, 2014

2014 Memphis British Car Show

September has been a busy month! After the Northwest Arkansas show, my own local show, the Memphis British/Euro Car show arrived. A much smaller show than the Arkansas show, but a lot of fun nonetheless.

I managed to squeak out a 2nd place in the Triumph category and even win a few door prizes. Bringing home some hardware makes a fun day even a little nicer.

I was also invited to have my car sit at show center for the duration of the show next to some much nicer cars and represent the Triumph Marque. Much appreciation to the show organizers for that. This was a very well organized show and a lot of fun.

There was a pretty nice variety of beautiful cars there. Below is only a small collection of the wonderful cars that were there.

I managed to squeak out a 2nd place in the Triumph category and even win a few door prizes. Bringing home some hardware makes a fun day even a little nicer.

I was also invited to have my car sit at show center for the duration of the show next to some much nicer cars and represent the Triumph Marque. Much appreciation to the show organizers for that. This was a very well organized show and a lot of fun.

There was a pretty nice variety of beautiful cars there. Below is only a small collection of the wonderful cars that were there.

Tuesday, September 23, 2014

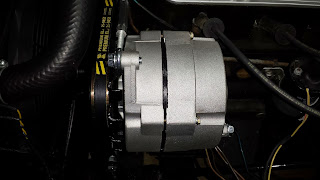

GM 10SI Alternator Upgrade for Triumph TR6

Like many, my car still wore a Lucas alternator until recently. Unfortunately, the alternator was really showing its age. In normal driving it kept up reasonably well. However, I have an electric cooling fan, fog lights and a radio and amp in the trunk. With any combination of those things on, it quickly showed it was incapable of keeping up. In spite of the terrible Lucas reputation, that alternator served me well for 24 years and a spectacular amount of miles.

I decided to upgrade my car and started researching what alternator to go with. There are several options out there. What I found is:

- Plug N Play options which are becoming hard to find and could be pricey

- Inexpensive options which require some modifications but are plentiful

I searched for the Plug N Play Ford Fiesta Alternator and despite links sent to me by friends and chasing a lot of different leads, I never got my hand on a good alt. I actually at one point ordered one from a vendor in NY, only to have it arrive and find that it had the wrong casting to mount to a TR (though the photo on the website showed the correct casting). The scarcity of this option pushed me away from it.

I then went looking for Instructions on how to go down the inexpensive/plentiful path that required some modifications and engineering. Once I finally found a couple websites that had some good ideas and instructions I dug in. Here are the links I followed.

www.mntriumphs.org/aOLD/Tech.../Delco_Alternator_Conversion.pdf --- Excellent How-to that covers the '73 car and a Delco Alt (Much credit to the author of this document, as I followed this one very closely to convert my car)

www.vtr.org/maintain/alternator/conversions.shtml --- Some info from Dan Masters on several years, and several different examples.

To start, I had to remove my old alternator. I also cut loose the old connectors. ****** Before doing any of that, I disconnected the battery****** I decided to leave approximately 2" of wire on the connectors just in case I ever wanted to reattach them for some unknown reason.

The alternator I decided to use is a Delco 10SI alternator. This is a very good choice as it puts out 63 amps max. It is also good because it starts up at a lower shaft RPM than any other Delco alternator. That makes a difference!

I mounted up the alternator and fitted the belt to the front of the car.

The MNTriumphs PDF suggested the use of a turnbuckle as belt tensioner. I bought a stainless steel version (only the screw eyes are stainless, the center is alu). So far this setup is working quite well. Time will tell if lasts. Adjusting it is really nice and much easier than the stock adjustment that a TR normally has.

To wire mine up, I followed the instructions at the MN Triumphs PDF. I connectorized everything and covered them all with heat shrink for additional protection from shorts. The main power connections to the car come from ring connectors off the back of the alternator. (I plan to reconnectorize these to make them look a little better). I sourced some 10ga wire at Napa and ran a third brown wire from that power terminal to the power terminal on the starter. This is to protect the wiring harness from the higher power of the 10SI alternator. A word on Belts......

Since I changed pulley size slightly from both the original Lucas and Delco alts, and because the casing of the Delco alternator is a different size, I had to find a different belt for the car. I'm a bit embarrassed to say that I went through 5 different belts before I found just the right length for the car. However, I really wanted this length to be correct and the fit to be right. Getting it wrong would put the alternator too close to the engine and subject it to more heat than necessary. Doing so also put it much too close to my #1 spark plug and my fuel line.

to say that I went through 5 different belts before I found just the right length for the car. However, I really wanted this length to be correct and the fit to be right. Getting it wrong would put the alternator too close to the engine and subject it to more heat than necessary. Doing so also put it much too close to my #1 spark plug and my fuel line.

I also found that there are some pretty huge differences in belt quality.... I tried a couple different belts from Autozone (Duralast brand) and they set up such shaking and vibration in the alternator I was worried it would break the mount. It was terrible. I ended up settling on the top quality belt from Napa and with that belt, the fit was better, and the alternator ran smoothly. Much less in the vibration department.

For my setup, I ended up with a 45 3/8" belt. A lot of swapping of belts and lunch hours stopping by Napa and Autozone to swap belts, but I think the effort was worth it.

I decided to upgrade my car and started researching what alternator to go with. There are several options out there. What I found is:

- Plug N Play options which are becoming hard to find and could be pricey

- Inexpensive options which require some modifications but are plentiful

I searched for the Plug N Play Ford Fiesta Alternator and despite links sent to me by friends and chasing a lot of different leads, I never got my hand on a good alt. I actually at one point ordered one from a vendor in NY, only to have it arrive and find that it had the wrong casting to mount to a TR (though the photo on the website showed the correct casting). The scarcity of this option pushed me away from it.

I then went looking for Instructions on how to go down the inexpensive/plentiful path that required some modifications and engineering. Once I finally found a couple websites that had some good ideas and instructions I dug in. Here are the links I followed.

www.mntriumphs.org/aOLD/Tech.../Delco_Alternator_Conversion.pdf --- Excellent How-to that covers the '73 car and a Delco Alt (Much credit to the author of this document, as I followed this one very closely to convert my car)

www.vtr.org/maintain/alternator/conversions.shtml --- Some info from Dan Masters on several years, and several different examples.

To start, I had to remove my old alternator. I also cut loose the old connectors. ****** Before doing any of that, I disconnected the battery****** I decided to leave approximately 2" of wire on the connectors just in case I ever wanted to reattach them for some unknown reason.

The alternator I decided to use is a Delco 10SI alternator. This is a very good choice as it puts out 63 amps max. It is also good because it starts up at a lower shaft RPM than any other Delco alternator. That makes a difference!

The particular model/part number shown is clocked with the connectors toward the block. I re-clocked the connectors down so that washing the engine bay would not fill the alternator with water.

This alternator came with a pulley for a 3/8" belt. Not a problem if you have a later car or have replaced your Harmonic Balancer at some point (seems like only the 3/8" is available now). However, my car still has a 1/2" balancer. To make this work, I went to a local alternator shop near work and they found a pulley for a John Deere which fit perfectly. It is slightly larger (20% larger in circumference) so it runs the alternator a little slower. I did some math in a spreadsheet to ensure that it would still spin the alt shaft fast enough to produce the power I needed.

Next up, I had to modify my alternator. The stock Delco alternator has a mounting tab on the bottom with a 'boss' that sticks off the back approximately 3/4". I cut that off per what you see in the photo with my angle grinder with a cutoff wheel in it. I dressed it flat and perfectly straight with a file. That spacer is sticking out of it slightly, but it normally is inside.

I tried the alternator on the car, but found it would not mount up because the front engine plate edge was in the way. I had to grind the plate. Again I got out my angle grinder and used a grinding wheel to cut it down to size. I protected the engine bay while I did this as sparks were flying every where. I did paint it with a little black paint afterwards. It sure looked better in person (somehow everything I do looks worse when I take a photo of it....

Finally, it was time to mount the alt. The MNTriumphs PDF talks about making a bushing to size up the alternator to fit the 5/16" bolt that fits the block alternator mount. I cut a piece of old steel fuel line from the car the length of the alternator mounting tab. Then I split it lengthwise on one side and tapped my 4" long 5/16" mounting bolt down through it. It was a perfect fit and made a perfect fit to bush the 5/16" bolt up to the 3/8" ID of the alternator mount tab.This alternator came with a pulley for a 3/8" belt. Not a problem if you have a later car or have replaced your Harmonic Balancer at some point (seems like only the 3/8" is available now). However, my car still has a 1/2" balancer. To make this work, I went to a local alternator shop near work and they found a pulley for a John Deere which fit perfectly. It is slightly larger (20% larger in circumference) so it runs the alternator a little slower. I did some math in a spreadsheet to ensure that it would still spin the alt shaft fast enough to produce the power I needed.

I mounted up the alternator and fitted the belt to the front of the car.

The MNTriumphs PDF suggested the use of a turnbuckle as belt tensioner. I bought a stainless steel version (only the screw eyes are stainless, the center is alu). So far this setup is working quite well. Time will tell if lasts. Adjusting it is really nice and much easier than the stock adjustment that a TR normally has.

To wire mine up, I followed the instructions at the MN Triumphs PDF. I connectorized everything and covered them all with heat shrink for additional protection from shorts. The main power connections to the car come from ring connectors off the back of the alternator. (I plan to reconnectorize these to make them look a little better). I sourced some 10ga wire at Napa and ran a third brown wire from that power terminal to the power terminal on the starter. This is to protect the wiring harness from the higher power of the 10SI alternator. A word on Belts......

Since I changed pulley size slightly from both the original Lucas and Delco alts, and because the casing of the Delco alternator is a different size, I had to find a different belt for the car. I'm a bit embarrassed

I also found that there are some pretty huge differences in belt quality.... I tried a couple different belts from Autozone (Duralast brand) and they set up such shaking and vibration in the alternator I was worried it would break the mount. It was terrible. I ended up settling on the top quality belt from Napa and with that belt, the fit was better, and the alternator ran smoothly. Much less in the vibration department.

For my setup, I ended up with a 45 3/8" belt. A lot of swapping of belts and lunch hours stopping by Napa and Autozone to swap belts, but I think the effort was worth it.

Tuesday, September 16, 2014

6-Pack Calendar Shots

The 6-Pack Triumph club produces a calendar annually which few can compare with. This year, I was determined to get my car in the calendar. My trip to my father's local car show gave me a great opportunity to shoot my car and his in some great environments to get great photos.

The end result was that I shot photos which made up 2 of the 12 months worth of the calendar. Both my father's car and my own made it into the calendar- Miss April (Dad) and Miss October (my car).

Here are the results. These shots were taken over Eden Bluff on Beaver Lake in Northwest Arkansas.

The end result was that I shot photos which made up 2 of the 12 months worth of the calendar. Both my father's car and my own made it into the calendar- Miss April (Dad) and Miss October (my car).

Here are the results. These shots were taken over Eden Bluff on Beaver Lake in Northwest Arkansas.

Monday, September 15, 2014

2014 Northwest Arkansas British Iron Car Show

I had the opportunity to attend the 2014 Northwest Arkansas British Iron Car Show. To say it was an awesome show is a gross understatement. The event is well run, well attended and the fact that it is down the street from my parents' home makes it even better for me.

This year the guest of honor was Kas Kastner. I built my car per his performance manual, so meeting him was a treat. At one point, he spent nearly half an hour with me at my car asking questions about what things I had done to it to make it go fast. He would then go through how he came up with the idea for that modification and then developed it! Definitely a discussion I'll never forget!

There were definitely some pretty awesome cars there, here are a few of the sights!

This year the guest of honor was Kas Kastner. I built my car per his performance manual, so meeting him was a treat. At one point, he spent nearly half an hour with me at my car asking questions about what things I had done to it to make it go fast. He would then go through how he came up with the idea for that modification and then developed it! Definitely a discussion I'll never forget!

Attending the show with my mother and father was a pretty big highlight too! In the end, I took 2nd in early TR6, and Dad took 2nd in unrestored with his '74 TR6.

There were definitely some pretty awesome cars there, here are a few of the sights!

Subscribe to:

Posts (Atom)